Metal Grain Silo: What Should We Know About It

With the development of the era, the materials and functions of granaries are constantly changing. From the beginning of using wooden houses to store grain, to granaries made of brick walls and concrete, they have evolved into the most widely used metal grain silos. Metal grain silo, also called metal grain bin. Among them, the most practical and widely popular metal grain silo is the steel grain silo.Classification of metal grain silos

Steel silos are widely used in various industries, including cement silos, coal storage, chemical tanks, grain storage, etc. The metal grain silo we are concerned with here mainly refers to steel grain silos. According to the construction method, steel silos for grain storage can be divided into galvanized corrugated steel silos, spiral steel silos (also known as Lipp silos), and welded steel silos. They all play important roles in the field of grain storage. Here is a brief introduction to each of the three types:

Bolted Steel Silo (Galvanized corrugated steel silo):

The bolted steel silo, as known as the galvanized corrugated steel silo, has the characteristics of convenient industrial production, convenient transportation, fast silo construction, not affected by the construction season, high efficiency, and convenient demolition. All steel plates are made of high-quality hot-dip galvanized sheets; all parts are standard and replaceable. Manufacturers can easily replace damaged parts during use and extend the service life of the silo. The bolted silo can be rebuilt and dismantled, and the height and diameter of the bolted silo can be customized, making it ideal for large grain silos and oil plants.Spiral steel silo (Lipp silo):

The spiral steel grain silo incorporates the Lipp double-seaming technology, which is highly advanced in the silo construction industry. These spiral steel silos are capable of storing various granular or powdery bulk grains, such as rice, corn, wheat, soybeans, barley, sorghum, sunflower seeds, palm kernels, buckwheat, millet, bran, beans, rapeseed, sugar beet seed, peanuts, flour, feed, miscellaneous grains, and other crops. They meet the requirements for scientific, green, and ecological grain storage. Spiral steel silos can be customized in different sizes and configurations to suit various grain types. Their advantages include durability, ease of assembly, short construction periods, reduced labor requirements, excellent sealing, and suitability for automated, highly mechanized grain storage. The disadvantage is the limited capacity of a single silo, along with specific requirements for the process of steel plates, and requires associated maintenance costs.

Welded steel silo:

Welded silos are mainly used for storing powders, granules, and non-corrosive liquids. Their advantages include good airtightness, thick steel plate walls for high strength, and tall silo height, which results in a large storage capacity with almost no storage limitations. They also have good corrosion resistance and a long service life. Therefore, steel plate silos at coastal ports, due to the corrosion of steel plates by salt in the air, often use thick steel plate welded silos. However, at the same time, welded silos also have the disadvantages of being difficult to construct, high cost, and long construction cycles.Structures of the steel grain silo

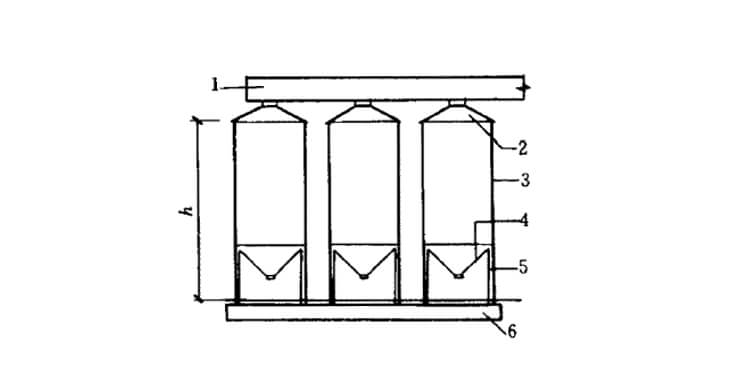

The structure of steel silos for grain storage consists of six parts. The uppermost part is called: the building above the top of the silo. Below is the top of the silo. The top of the silo usually contains the silo roof, safety guardrails, and process equipment. The next part is the silo wall. It refers to the silo wall, rest platform, silo gate, and ladder. The fourth part is the bottom of the steel silo and then there is the supporting structure of the silo and foundation.The steel grain silos sold by AGICO come with a complete set of automated supporting systems, including loading and unloading systems, cleaning systems, drying systems, material level monitoring systems, temperature measurement systems, ventilation systems, fumigation systems, electrical control systems, weighing and packaging systems. From material intake to discharge, every stage is digitally monitored and managed comprehensively, making the storage, circulation, and management of grains more scientific and secure.

How long does grain last in a silo?

If you intend to store grains in metal silos, these silos must possess certain characteristics, including moisture resistance, thermal insulation, ventilation, airtightness, pest and rodent resistance, fire resistance, suitability for mechanized operations, suitability for bulk grain storage, durability, and seismic resistance. Therefore, the use of steel silos generally requires complementary systems and processes for grain intake and discharge, ventilation, fumigation, grain condition monitoring and control, cleaning, dust removal, loading and unloading, material discharge, cooling, and explosion prevention. These complementary facilities ensure the safe storage of grains in steel silos.

So, how long can grains be stored in the metal grain silos provided by AGICO?

Generally speaking, with proper storage and monitoring, grains can be stored for over 1 year! Of course, different grains have different storage requirements and shelf lives, so their storage times in steel grain silos also vary. For example, for long-term storage grain reserves in steel plate silos: storage time can exceed 1 year. For bulk grain port transit steel plate silos: storage time is 2 to 3 months. For grain and oil processing plant steel plate silos: storage time is 1 to 2 months. Many factors can affect the storage lifespan of grains, so monitoring the storage area and regularly inspecting the grains are crucial.

Overall, metal grain silo storage is the most cost-effective, high-performance, and long-lasting storage system. It can effectively monitor the quality and quantity of grains in real-time, improve storage efficiency, and minimize grain damage within the silo storage system. The construction and maintenance costs of steel grain silos are significantly lower compared to traditional storage. In terms of environmental protection, metal grain silos utilize advanced dust removal technology and sealing performance, which can reduce the generation and spread of dust, protect the surrounding environment from pollution, and align better with the current trend of environmental protection and energy conservation.

Español

Español