Grain Silo Maintenance and Cleaning Instructions

If grain is to be properly stored after harvest, it is necessary to use grain silos. However, when using steel silos, if we do not pay attention to some details, it is likely to cause accidents. Regular maintenance and cleaning of your grain silo can ensure that the silo is always in good condition and avoid accidents.Before the maintenance work begins, we need to empty the steel silo and walk around it to visually inspect the condition of its overall structure and base.

Workers must pay attention to the following points before entering the granary for maintenance:

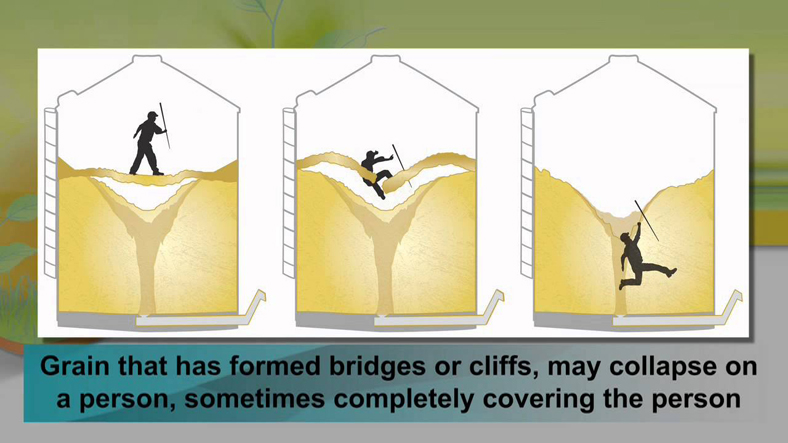

- Make sure the silo is totally emptied. No one is allowed to enter the silo until the material stored inside is cleaned out.

- Double check your protective gear. Only those who are properly equipped with safety protection equipment can enter the silo.

- Make sure that the power supply to the operating system and accessories of the steel silo has been completely shut down to prevent accidents.

What do we need to check?

Check the silo’s structural integrity. Soil erosion around or below the grain silo foundation will jeopardize the structural integrity of the grain silo; in winter, frost on the silo surface need to be removed to ensure the silo’s structural integrity.

Check if there are any weeds or trash near the silo. Weeds and trash may raise bugs and attract pests, which will do harm to grain silos and the grain stored in them. If you find any traces of bugs or pests, take immediate measures to exterminate them.

Inspect the grain silo wall for signs of rust and buckling. Due to the influence of moist grain, metal corrosion may occur in the silo wall of grain steel silos. Steel rust could damage the integrity of the silo wall, resulting in air tightness decreasing or material leakage. The steel silos should be inspected by experts before they can be put into use again. Repairs may be required for serious situations.

Look for any cracks or any deformation on the silo wall. Cracks and deformation are serious problems, they must be found and solved at the first time, otherwise they will easily lead to safety accidents.

Check the double-seaming positions on the grain silo. Make sure the seaming parts are well sealed.

Check if all the ancillary equipments are functioning properly. Timely repair or replacement should be carried out for defective ones.

The seal around the bottom of the silo should be closely inspected as there will be tremendous force applied to it when the grain silo is fully charged. Broken seals will result in moisture ingress and potential grain spoilage, and shorten the silo’s service life.

Grain Silo Cleaning

Any residue of grain left in the grain silo is a source of insects or molds that can contaminate your newly harvested grain and spoil it.

Grain silos should be vacuumed to remove residual dust, mold, and old grains. After cleaning, make sure that all seams, flanges, and floors in the silo are free of debris and dust. For areas stained with dirt and grain, use clean water wipe and brush them, then thoroughly dry them.

Flyer steel silos have long been used as an integral component of commercial grain management systems. Now, they are available in various sizes and are ideal farm owners. If you have any thoughts on our grain silos, please do not hesitate to let us know!

Español

Español