How to Solve the Problem of Coal Arch Blocking and Dust Explosion?

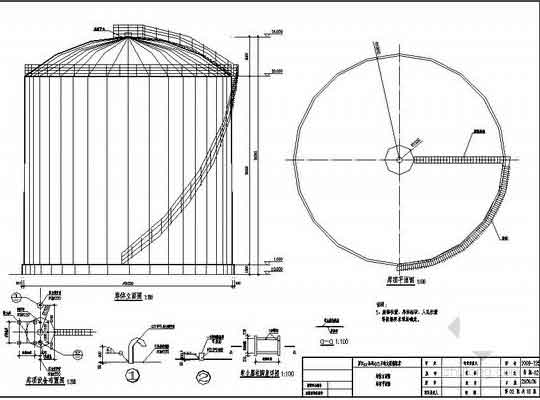

Due to the poor mobility of coal, the discharge mode of the steel silo for the storage of coal usually use inverted cone. Cone wall angle should be greater than 45 degrees, easy for discharge. Discharge port can be used with double feed port, multiple feed port etc. In order to prevent eccentric unloading, to ensure that the main structure of the silo is balanced and the discharge port should be symmetrically arranged.

Coal Arch Blocking of Steel Silo

Application of large capacity Philips silo in the coal storage and transportation, are more prone to arch blocking phenomenon. There has many existing coal bunker arch breaking method. Commonly used Artificial broken arch method, Hydraulic broken arch method, Wind broken arch method, Vibrator broken arch method, Air guns, etc. Should according to the specific circumstances of Lipp Silo choose one or more methods.

Dust Explosion of Steel Silo

Coal in the long-term storage of steel silo prone to spontaneous combustion. In the process of spontaneous combustion, it not only releases heat, but also releases combustible gas with different content. When the temperature, the concentration of combustible gas and dust concentration reaches a certain value, the steel silo is very easy to explode, and the measures to prevent explosion should be taken.

- Enter the inert gas in the steel silo, to reduce mixture of dust and combustible gas. Destroy the combustion condition of coal dust and flammable gas, to avoid explosion.

- Build ventilation system, using thermal insulation system to shorten the coal storage cycle.

- Establish GD2000 combustible gas detector matching use with combustible gas alarm controller, composition of Lipp Silo safety inspection system, timely and accurately find abnormal situation. When there is a combustible gas in the silo, the detector can immediately send out the electrical signal which is proportional to the content of the combustible gas in the air. Signal transmitted to the alarm controller can display (or record) the concentration of combustible gas in the air, at the same time sent out sound, light alarm and control signal, so as to ensure the safety of production, to avoid the occurrence of malignant events.

This automation industrial production can effectively reduce the labor cost and improve the production efficiency.

Kind Notice: Here are more discharging modes of steel silo that you may also want to know about.

Español

Español